HOUSEKEEPING

House keeping can be referred to as operations such as maintenance or record-keeping which facilitate productive work in an organization. When implementing house keeping there are a few requirements that has to be met. Such require are :

the ability to encourage and motivate staff.

planning and organisational skills.

the ability to cope with problems and emergencies, and make effective decisions.

numerical ability.

use proper tools to carry out housekeeping

|

Importance of housekeeping

Effective housekeeping can eliminate some workplace hazards and help get a job done safely and properly. Poor housekeeping can frequently contribute to accidents by hiding hazards that cause injuries. Good housekeeping is also a basic part of accident and fire prevention. The importance of housekeeping can be categorized as preventing harm to others, yourself and components. THis will also make a good impression with customers or guest.

Cleaning work area

When cleaning a work area there are some things that should be taken into consideration. When cleaning work area or tools it is important that safety is observed, always read all instructions before starting to implement cleaning the area. When having a clean work area it will be a lot more organized, space is a big issue because a lack of space will affect the quality of work that the technician is expected to deliver. There are some specific tools that are required for house keeping these are:

Dustpan - They are used to collect dust and garbage from the floor and putting it into the dustbin.

Dusting Cloths - They are soft cloths used for wiping dust off surface.

Mops - Swiffer's and other waterless mopping systems may work great for light clean-ups, but for thorough floor cleaning you need a good mop

broom - a broom must be part of your tools. The ones with soft flexible bristles will pick up more dust and get into those hard to reach places.

buckets – When using mops and rags, sturdy buckets are an essential part of your housekeeper’s toolkit. You’ll need a couple different sizes for big jobs like mopping floors and smaller ones for other cleaning tasks.

Rags -Nothing beats good old cleaning rags for those tough, dirty projects. Old towels, T-shirts and socks all make good cleaning rags. They can be washed and reused many times before wearing out.

Brushes − They are handheld flat brushes with bristles to dust the plain surfaces as well as the corners. They come with non-slip handles and stiff scratch-free bristles. They help removing stubborn dust.

Janitor’s trolley − It is a trolley that stores cleaning supplies such as detergents, spray bottles, dustbin, mop, and dusting cloths, all in a compact manner

Steps for when cleaning a work area are:

Rough Cleaning

- First remove all debris either by hand or use of brushes, brooms, scrapers, squeegees, etc.

- Collect and dispose of all debris appropriately (e.g. inedible containers).

- A warm rinse is recommended to complete the rough cleaning.

Chemical Cleaning and Sanitation

- After rough cleaning, apply an appropriate application of cleaning agents to surfaces and equipment. Concentrations to use are in accordance with the manufacturer’s recommendations.

- Scrub all surfaces manually or mechanically.

- Make sure equipment used for cleaning and sanitizing is kept in clean and sanitary condition (e.g. hand held hoses) to prevent cross contamination.

- Apply cleaning agents to production areas, including walls and floors.

Rinsing

- After chemical cleaning and scrubbing, rinse all areas and equipment with hot potable water.

- After rinsing, check surfaces to ensure that all grease and debris has been removed. This should be done by physical touch.

- Repeat above steps if necessary.

Sanitizing

- After rinsing, apply an approved sanitizer.

- Sanitizers are only effective on surfaces that have been thoroughly cleaned.

- Use sanitizing agents as per manufacturer’s recommendations. This is especially important since some sanitizers require a final rinse and some do not.

Removal of Excess Water

- Any areas where water has extensively pooled may serve as a medium for bacteria growth and should be dried.

- Equipment that has the potential to rust should also be dried.

computer parts disposal, electronic recycling or e-waste recycling is the disassembly and separation of components and raw materials of waste electronics This would typically include printed circuit boards (PCBs) such as motherboards, power supplies, graphics cards, memory RAM sticks and hard drives. Although the procedures of re-use, donation and repairs are not strictly recycling, there are other common sustainable ways to dispose of IT waste.

Most Effective Hazard Controls. The best way to protect workers is to remove or eliminate the hazard from the workplace using the following hazard control methods: Substitution. Substitute dangerous chemicals, equipment or work methods with safer and less hazardous ones to eliminate the hazard altogether.

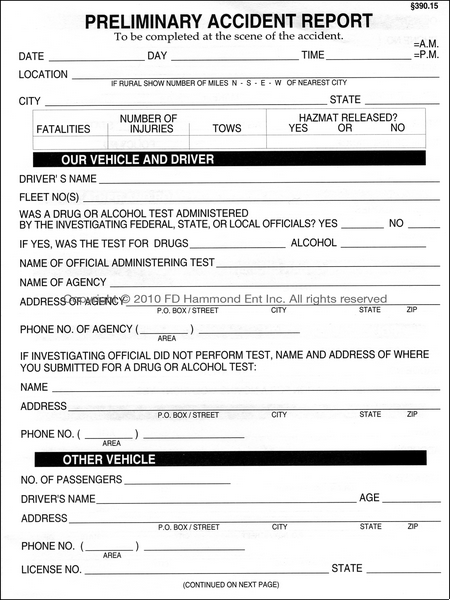

When housekeeping was not implemented in a establishment there is a high risk of accidents that will occur.If for any reason there was an accident the method would be to, make sure you record any injury in the 'accident book' if need be, make sure your employer has reported it to the HSENI. check your contract or written statement of employment for information about sick or accident pay.